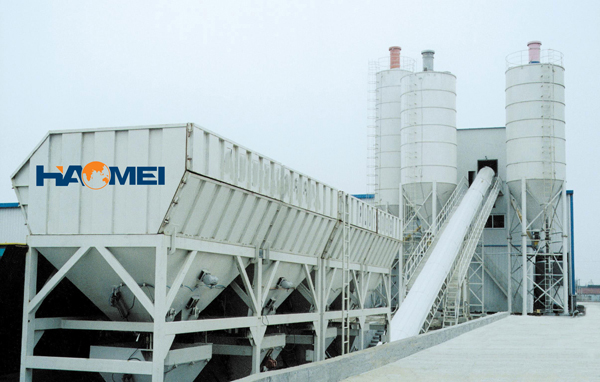

rmc plant construction & design

-1864 items in Type

This is a 30 m3/hr. ready mix machine designed for producing concrete in batches. This rmc plant construction & design is easy to move and shift places

More DetailsProduct Information

thermc plant construction & designis used to manufacture ready-mix concrete which is used in all the construction projects. The ready-mix concrete is also known as RMC is a mixture of cement, water, sand and aggregates. It is manufactured in a rmc plant construction & design as per the required specifications of a construction project. RMC (ready mix concrete) commonly refers to the concrete which is freshly pre-mixed and delivered in unhardened state which can form any shape. It is prepared by mixing cement, gravel, crushed stone, sand, water etc., which depends on the type of the construction project. After the preparation of ready mix concrete, it is then delivered to the construction site through truck or transit mixer which is capable of mixing the ingredients of the concrete while travelling. Manufacturing ready mix concrete and delivering through a transit mixer enables the implementation of precise concrete in the construction project making it sturdy, strong and long lasting.

Parameters of rmc plant construction & design

| Model | HZS25 | HZS35 | HZS50 | HZS75 | |

| Theoretical output(m³/h) | 25 | 35 | 50 | 75 | |

| Mixer model | JS500 | JS750 | JS1000 | JS1500 | |

| Output per batch(m³) | 0.5 | 0.75 | 1 | 1.5 | |

| Aggregate batcher | PLD800 | PLD1200 | PLD1600 | PLD2400 | |

| Total power(KW) | 27 | 35 | 80 | 110 | |

| Aggregate weighing accuracy(%) | (0-1500)kg±2% | (0-2250) kg±2% |

(0-2500)kg±2% | (0-4000) kg±2% | |

| cement weighing accuracy(%) | (0-300)kg±1% | (0-400)kg±1% | (0-500) kg±1% |

(0-800) kg±1% |

|

| water weighing accuracy(%) | (0-200)kg±1% | (0-300)kg±1% | (0-300)kg±1% | (0-500)kg±1% | |

| fly ash weighing accuracy(%) | (0-300)kg±1% | (0-300)kg±1% | (0-300)kg±1% | (0-500)kg±1% | |

| additive weighing accuracy(%) | (0-40)kg±1% | (0-40)kg±1% | (0-40)kg±1% | (0-50)kg±1% | |

| Discharge height(m) | 3.8-4.1 | ||||

| Max. aggregate dia.(mm) | 60 | 60 | 80 | 80 | |

| Cement silo and screw conveyor | On request | ||||

| Total weight (ton) | 20 | 25 | 35 | 45 | |

| Overall dimension(LxWxH)(m) | 11.5x5.8x19.4 | 12x6x19.4 | 20.5x7.5x19.4 | 25.9x9.2x19.4 | |

Parameters of Belt conveyor type rmc plant construction & design

| Model | HZS60 | HZS90 | HZS120 | HZS180 | HZS240 |

| Theoretical output(m³/h) | 60 | 90 | 120 | 180 | 240 |

| Mixer model | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

| Output per batch(m³) | 1 | 1.5 | 2 | 3 | 4 |

| Aggregate batcher | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Total power(KW) | 110 | 145 | 160 | 205 | 340 |

| Aggregate weighing accuracy(%) | (0-3000)kg±2% | (0-4000)kg±2% | (0-4500)kg±2% | (0-4500)kg±2% | (0-6000)kg±2% |

| cement weighing accuracy(%) | (0-600)kg±1% | (0-1000)kg±1% | (0-1200)kg±1% | (0-1800)kg±1% | (0-2400)kg±1% |

| water weighing accuracy(%) | (0-400)kg±1% | (0-400)kg±1% | (0-600)kg±1% | (0-800)kg±1% | (0-1000)kg±1% |

| fly ash weighing accuracy(%) | (0-400)kg±1% | (0-400)kg±1% | (0-600)kg±1% | (0-800)kg±1% | (0-700)kg±1% |

| additive weighing accuracy(%) | (0-40)kg±1% | (0-40)kg±1% | (0-50)kg±1% | (0-50)kg±1% | (0-120)kg±1% |

| Discharge height(m) | 3.8-4.2 | ||||

| Max. aggregate dia.(mm) | 80-100 | ||||

| Cement silo and screw conveyor | On request | ||||

| Total weight (ton) | 46 | 60 | 71 | 87 | 112 |

| Overall dimension(LxWxH)(m) | 33.8x14.8x19.4 | 38x16x19.4 | 44x18x19.4 | 58.5x23.5x22 | 60x25x22 |

Advantages of Using rmc plant construction & design

rmc plant construction & design being on-site concrete mixing plant, enables precision of the mixture and reduces worksite confusion. Before, the concrete was prepared manually, but now it is being prepared using computer controlled operations which is known as ready mix concrete plan having many advantages, some of them are given below:-

Facilitates speedy construction through programmed delivery at site and mechanized operation with consequent economy.

Thermc plant construction & design decreases labour, site supervising cost and project time. It also helps in proper control and economy over the raw material used which results in savings.

As the rmc plant construction & design is totally computerized, it guarantees the delivery of consistent ready mix concrete. The concrete mixed in ready mix concrete plant is not only consistent but accurate in quality and is manufactured as per the proportion of water and other material specified.

The ready mix concrete plant minimizes the cement wastage as it manufactures concrete in bulk quantity.

The rmc plant construction & design is a centrally located factory on site and so can maintain dust free atmosphere which prevents pollution.

Tag

rmc plant construction & design,rmc,plant,construction,,design

rmc plant manufacturer in ahmedabad

New | rmc plant

Component part of this rmc plant manufacturer in ahmedabad: JS concrete mixer, PLD batching machine, cement silo and control system. Field of using:.

View Details

rmc plant in unnao

New | rmc plant

We are a single-source supplier of china rmc plant in unnao and mixing solutions that supports all concrete products industries.

View Details

rmc plant photo

New | rmc plant

Find your rmc plant photo easily amongst the 227 products from the leading brands

View Details

rmc plant job in pune

New | rmc plant

The haomei Self Erecting rmc plant job in pune has a Twin Shaft Mixer mounted to the frame for superior mixing actions and the best quality concrete. The plant self erects for maximum portability.

View Details

rmc readymix plant

New | rmc plant

rmc readymix plant have been designed on towable chassis on wheels for maximum mobility and fast installation.

View Details

rmc plant hyderabad

New | rmc plant

rmc plant hyderabad. Compact, reliable and offering full performance. Plants with small-scale concrete mixer and a high production

View DetailsContact Details

Email:Mail:info@hmconcreteplant.com

Email:Mail:wade@haomei.biz

Tel (86) 371-6562-1392Fax (86) 371-8661-6825

web:concrete-machine.com

3 Items in your cart

3 Items in your cart

SOCIAL MEDIA