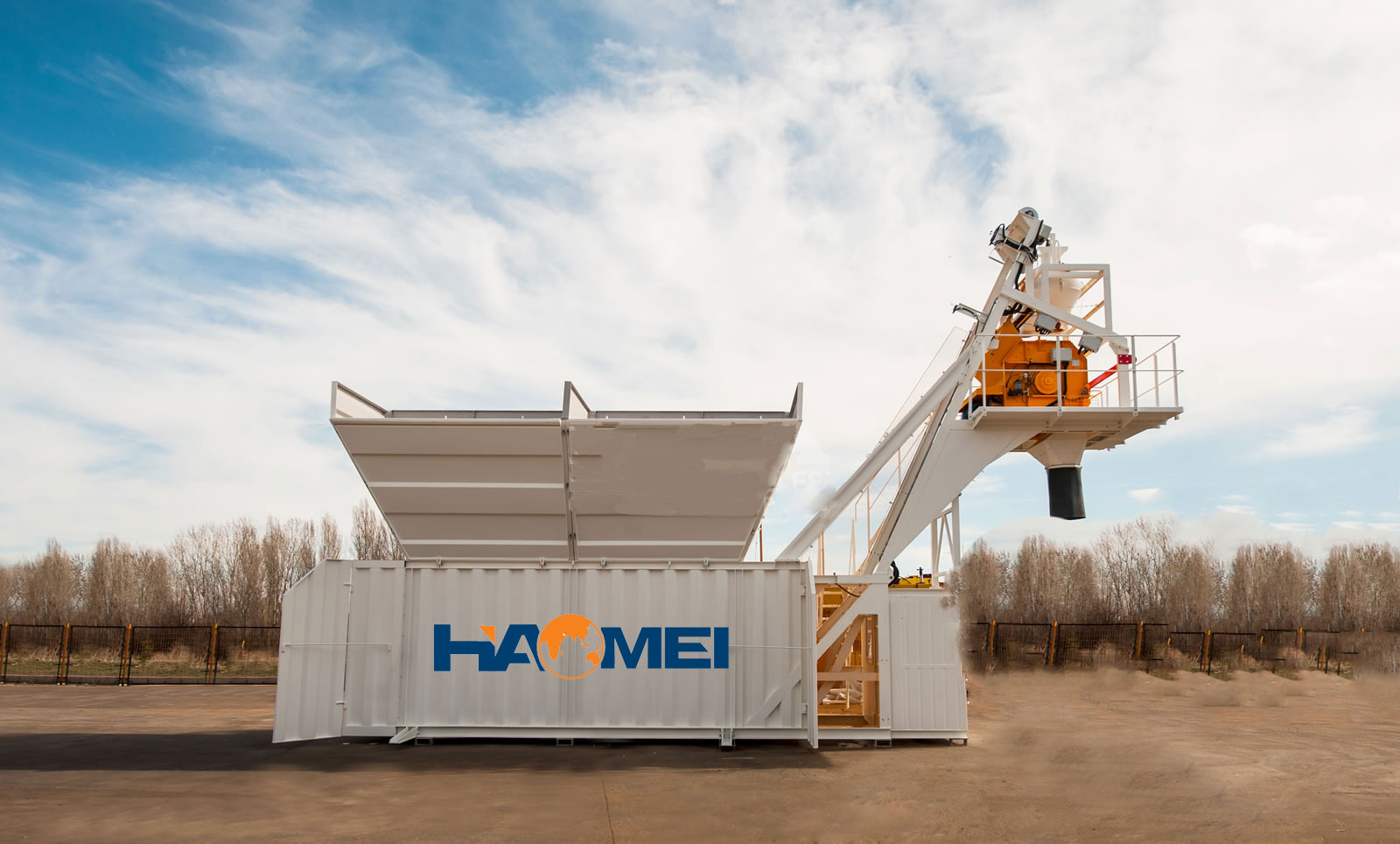

mobile tarmac batching plant

-1467 items in Type

25-400m³/h Mobile/Stationary/Semi-Portable mobile tarmac batching plant, Free Technical Guidance, Choose Haomei As Your Best Partner!

More DetailsProduct Information

The mobile tarmac batching plant is a concrete production equipment that concentrates the material storage, weighing, conveying, stirring, unloading and fully automatic control system of the concrete mixing plant and a dragging unit; It is the same as all the action processes, operation methods and maintenance of the fixed automatic mixing station; At the same time, it has the unique characteristics such as flexible movement, quick and simple disassembly, simple storage management, etc.. It is an excellent model for mobile construction of public railways, bridges, ports, and other projects.

mobile tarmac batching plant main technical specifications

| Model | YHZS60 | YHZS60 | YHZS75 | YHZS100 |

| Theoretical productivity | 50 | 60 | 75 | 100 |

| Unloading height | 4 | 4 | 4 | 4 |

| Aggregate storage bin capacity | 10 | 10 | 16 | 16 |

| Aggregate number | 2-4 | 2-4 | 2-4 | 2-4 |

| Transmission capscity of inclined belt conveyer | 300 | 300 | 280 | 280 |

| The maximum transmission capacity of serew conveyer | SJ1000 | SJ1000 | SJ1500 | SJ2000 |

| The power | 75 | 75 | 100 | 115 |

| Aggregate weighing range and accuracy | 2400±2% | 2500±2% | 3600±2% | 4800±2% |

| Powder weighing range and accuracy | 600±1% | 600±1% | 900±1% | 1200±1% |

| Water weighing range and accuracy | 300±1% | 300±1% | 400±1% | 500±1% |

| Additive weighing range and accuracy | 20±1% | 30±1% | 30±1% | 30±1% |

Main features of mobile tarmac batching plant:

1,rapid disassembly, easy to move

With the exception of external equipment such as spiral conveyor and cement warehouse, all the wiring of the mixing station does not need to be removed. It only takes 30 tons of crane to cooperate and can be removed in one day. When installing, if the ground is flat and solid, no foundation is required. Production can be put in place on the same day. It is very suitable for units with tight construction requirements.

The station is equipped with tires and tractor pins, allowing up to 50 km/h when dragged by a trailer. The total weight of all equipment at the mixing station is about 21 tons, and all accessories are removed at the station.

2,good mixing performance

The use of a strong double shaft mixer can be used for the shortest mixing time to achieve uniform stirring. For dry hard, semi-dry hard, plastic and various proportions of concrete can complete a good stirring.

3,high-grade configuration, high reliability, accurate measurement, convenient operation

The main electrical components of the mixing engine reducer, metering sensor, and control system are all imported components, which not only greatly reduces the failure rate of the equipment, but also improves the measurement accuracy of the equipment.

The whole machine adopts computer control, which can be operated automatically or manually. The operation is simple and easy to master. Dynamic panel display, can clearly understand the operation of the components, at the same time can store and print report data, for production scheduling management provides great convenience.

Packaging & Shipping

1. Packaging

A. 40' HQ containers will be needed;

B. A wooden-box with the size of 60cm*60cm*60cm will be used for small items like bolt, nult, screw etc.

2. Shipping :

by sea or by train; we have rich experience of shipping by sea or by train;

| By Sea | By Rail | |

| If there are special circumstances we can decide according to your request. | ||

| Payment Terms | 30% of total price shall be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery. |

|

| Delivery Time | 7 working days after receiving down payment | |

Our Services

1. Any inquiry will be replied within 12 hours.

2. Well-trained and experienced staff to answer all your inquiries in fluent English and Russia.

3. Factory visit is welcomed and free airport pick up service.

4. Engineers will go to clients' site for guiding the installation and test-running.

5. Spare parts supply,We will keep your know the complete data, when you need any spare parts, we will send to you in a fast way.

6. 12 months super long time guarantee period.

7. Customer-designed is received.

Tag

mobile tarmac batching plant,mobile,tarmac,batching,plant

mobile batching plant concrete

New | mobile batching plant

Manufacturing, Supplying and Selling the full range of haomei mobile batching plant concrete including Fixed, Compact and Mobile Concrete Plants.

View Details

groundworks mobile concrete batching plant

New | mobile batching plant

groundworks mobile concrete batching plant is mainly composed of five main systems, which are the mixing host, material weighing system, conveying ...

View Details

plant mobile concrete batching plant

New | mobile batching plant

haomei machinery is a leading supplier of highly durable plant mobile concrete batching plant.

View Details

mobile concrete batching plant capacity

New | mobile batching plant

The mobile concrete batching plant capacity can be a commercial concrete batch plant or a temporary batch plant brought in and assembled by the contractor near the paving site.

View Details

mobile concrete batching plant hs code

New | mobile batching plant

This is a 30 m3/hr. ready mix machine designed for producing concrete in batches. This mobile concrete batching plant hs code is easy to move and shift places

View Details

mini mobile batching plant price

New | mobile batching plant

haomei machienry supplies mini mobile batching plant price and Cement Silos. All models can be custom built and are easily transported from site to site, saving you time.

View DetailsContact Details

Email:Mail:info@hmconcreteplant.com

Email:Mail:wade@haomei.biz

Tel (86) 371-6562-1392Fax (86) 371-8661-6825

web:concrete-machine.com

3 Items in your cart

3 Items in your cart

SOCIAL MEDIA