dry mix concrete truck

-1492 items in Type

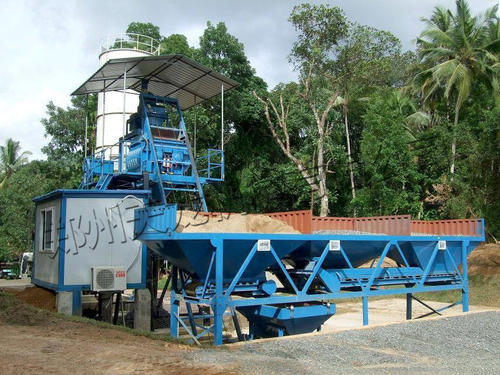

This aggregate Fast-Way batch plant can be ready to produce concrete minutes after it reaches the job site! When you use our dry mix concrete truck

More DetailsProduct Information

A dry mix concrete truck also known as Transit Mix Plant, weighs sand, gravel and cement in weigh batchers via digital or manual scales . All the ingredients then are discharged into a chute which discharges into a truck. Meanwhile, water is either being weighed or volumetrically metered and discharged through the same charging chute into the mixer truck. These ingredients are then mixed for a minimum of 70 to 100 revolutions during transportation to the job site.

Like a mobile concrete plant and a stationary concrete plant, the dry mix concrete truck consists of cement silos, feeding system, control system, weighing system and mixing system. Cement silos are the catching and supply of raw materials such as cement, sand and fly ash as production necessitates. The feed system is a bridge to connect the aggregates and the mixing system. The accuracy of the weighing system determines the amount of mixed materials, and therefore has a great influence on the quality of the mixed concrete. The mixing system only mixes the materials without water. As a result, the mixer truck is important for transporting and mixing concrete. The control system is the core of the whole plant. Workers can reach full automation by using concrete equipment in the control room.

Technical parameters of dry mix concrete truck

|

Model |

HZS25 |

HZS35 |

HZS50 |

HZS60 |

HZS75 |

HZS90 |

HZS120 |

HZS150 |

HZS180 |

|

Discharging Capacity (L) |

500 |

750 |

1000 |

1000 |

1500 |

1500 |

2000 |

2500 |

3000 |

|

Charging Capacity(L) |

800 |

1200 |

1600 |

1600 |

2400 |

2400 |

3200 |

4000 |

4800 |

|

Maximum Productivity(m³/h) |

25 |

35 |

50 |

60 |

75 |

90 |

120 |

150 |

180 |

|

Charging Model |

Skip Hopper |

Skip Hopper |

Skip Hopper |

belt conveyor |

Skip Hopper |

belt conveyor |

belt conveyor |

belt conveyor |

belt conveyor |

|

Standard Discharging Height(m) |

1.5~3.8 |

2~4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

3.8~4.5 |

4.5 |

4.5 |

|

Number of Species of Aggregate |

2~3 |

2~3 |

3~4 |

3~4 |

3~4 |

4 |

4 |

4 |

4 |

|

Maximum Aggregate Size(mm) |

≤60mm |

≤80mm |

≤80mm |

≤80mm |

≤80mm |

≤80mm |

≤120mm |

≤150mm |

≤180mm |

|

Cement/Powder Silo Capacity(set) |

1×100T |

2×100T |

3×100T |

3×100T |

3×100T |

3×100T |

4×100T or 200T |

4×200T |

4×200T |

|

Mixing Cycle Time(s) |

72 |

60 |

60 |

60 |

60 |

60 |

60 |

30 |

30 |

|

Total Installed Capacity(kw) |

60 |

78.5 |

111 |

145 |

110 |

198.06 |

210 |

230 |

288 |

Advantages of dry mix concrete truck

It has higher capacity and lower energy consumption because concrete can be mixed without water

- The cooperation between thedry mix concrete truck and the mixer truck can increase productivity and save time.

- The fresh concrete can be used because of the mixer trucks arrive at the construction site.

- It shortens the construction and enhances productivity.

- It’s got lower power consumption when compared to the wet mix plant.

- Operating costs of dry mix concrete truck are relatively low

- Allows concrete to be mixed more efficiently.

- It could be the short time period of maintenance needed when compared with wet mix plants.

- As in other mixing plants, such as mobile and stationary concrete plants, the dry concrete plant is also automated.

- If the site is quite long, it is an ideal choice for dry mix concrete truck manufacturers. While the mixer truck going to the construction site, it may keep the rotation order to prevent tampering, hardening of the mixed concrete and to ensure the freshness of the materials.

- Dry batch concrete vegetation is much-welcomed modern concrete production equipment that is constantly significantly assist in the development and development of modern roads, bridges and various concrete construction works.

Tag

dry mix concrete truck,dry,mix,concrete,truck

conmix dry mix concrete

New | Dry mix Concrete Plant

conmix dry mix concrete They are ideal equipments for construction-use concrete markets, and fit for different buyers with flexible investment requirements.

View Details

dry concrete mix design

New | Dry mix Concrete Plant

dry concrete mix design means they can deliver concrete to the most remote sites!

View Details

dry mix concrete calculator

New | Dry mix Concrete Plant

Welcome to the premier industrial dry mix concrete calculator: Concrete Batching resource. A wide variety of manufacturers, distributors and service companies are featured in our .

View Details

dry mix concrete definition

New | Dry mix Concrete Plant

The dry mix concrete definition is one of our best sellers. The mobility gives it flexibility in use delivering good returns on investment

View Details

bags of dry mixed concrete

New | Dry mix Concrete Plant

Concrete is composed essentially of water, cement, sand. (fine aggregate) and coarse aggregate, and is produced at bags of dry mixed concrete that concrete machine Online store

View Details

dry mix wet mix concrete

New | Dry mix Concrete Plant

A dry mix wet mix concrete, also known as a concrete plant, is a facility that combines raw materials such as sand, water, aggregate, cement, and others to create

View DetailsContact Details

Email:Mail:info@hmconcreteplant.com

Email:Mail:wade@haomei.biz

Tel (86) 371-6562-1392Fax (86) 371-8661-6825

web:concrete-machine.com

3 Items in your cart

3 Items in your cart

SOCIAL MEDIA